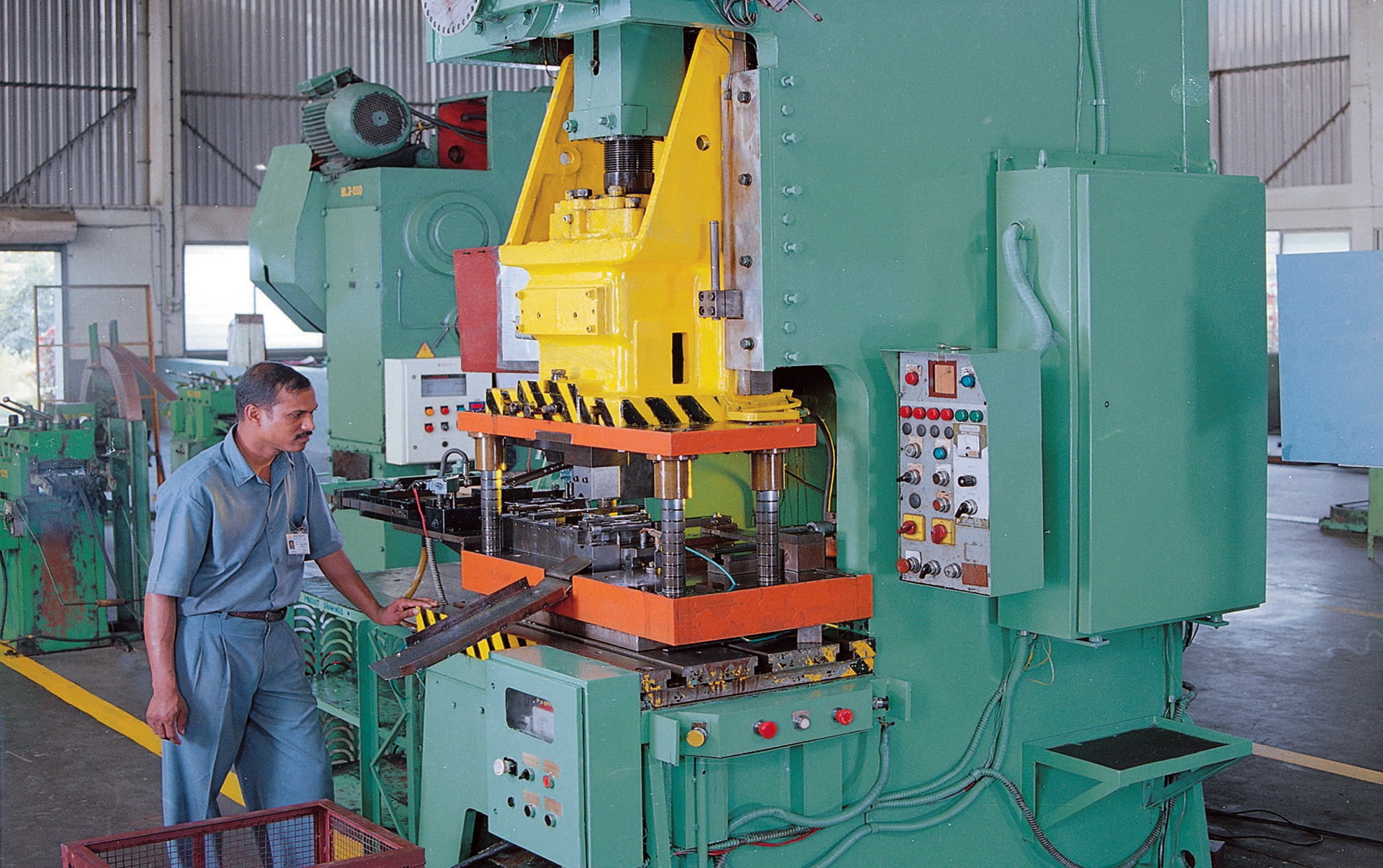

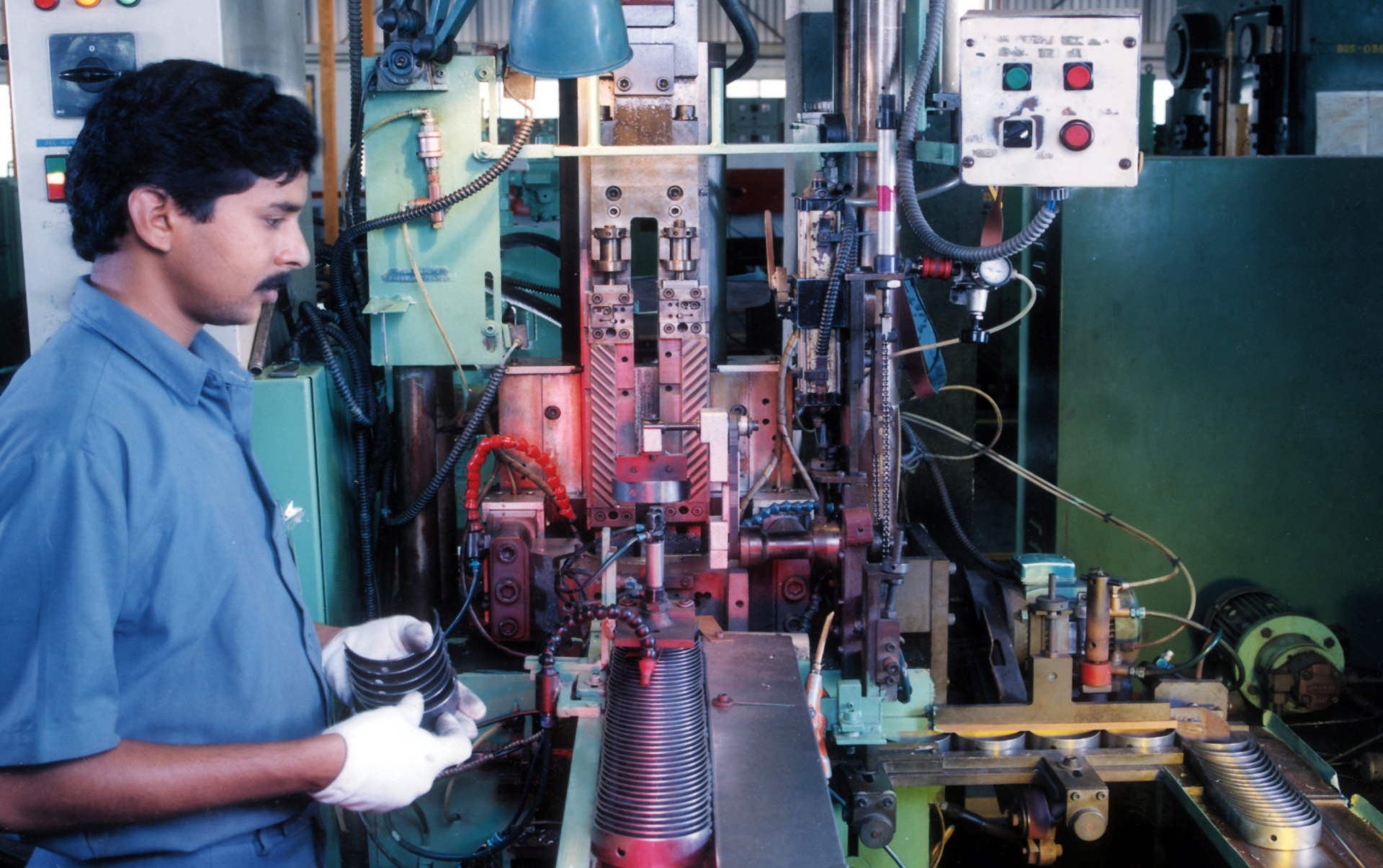

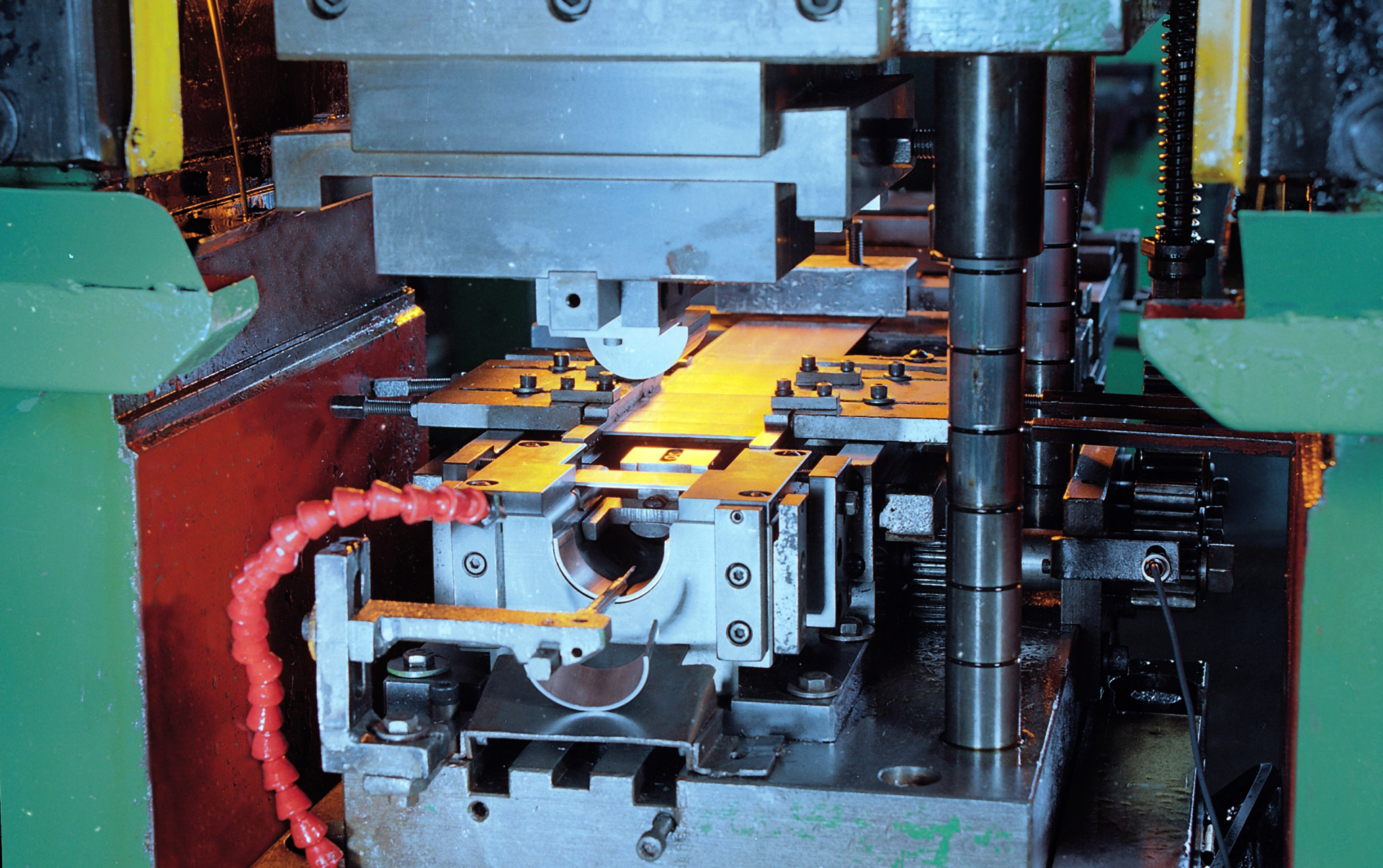

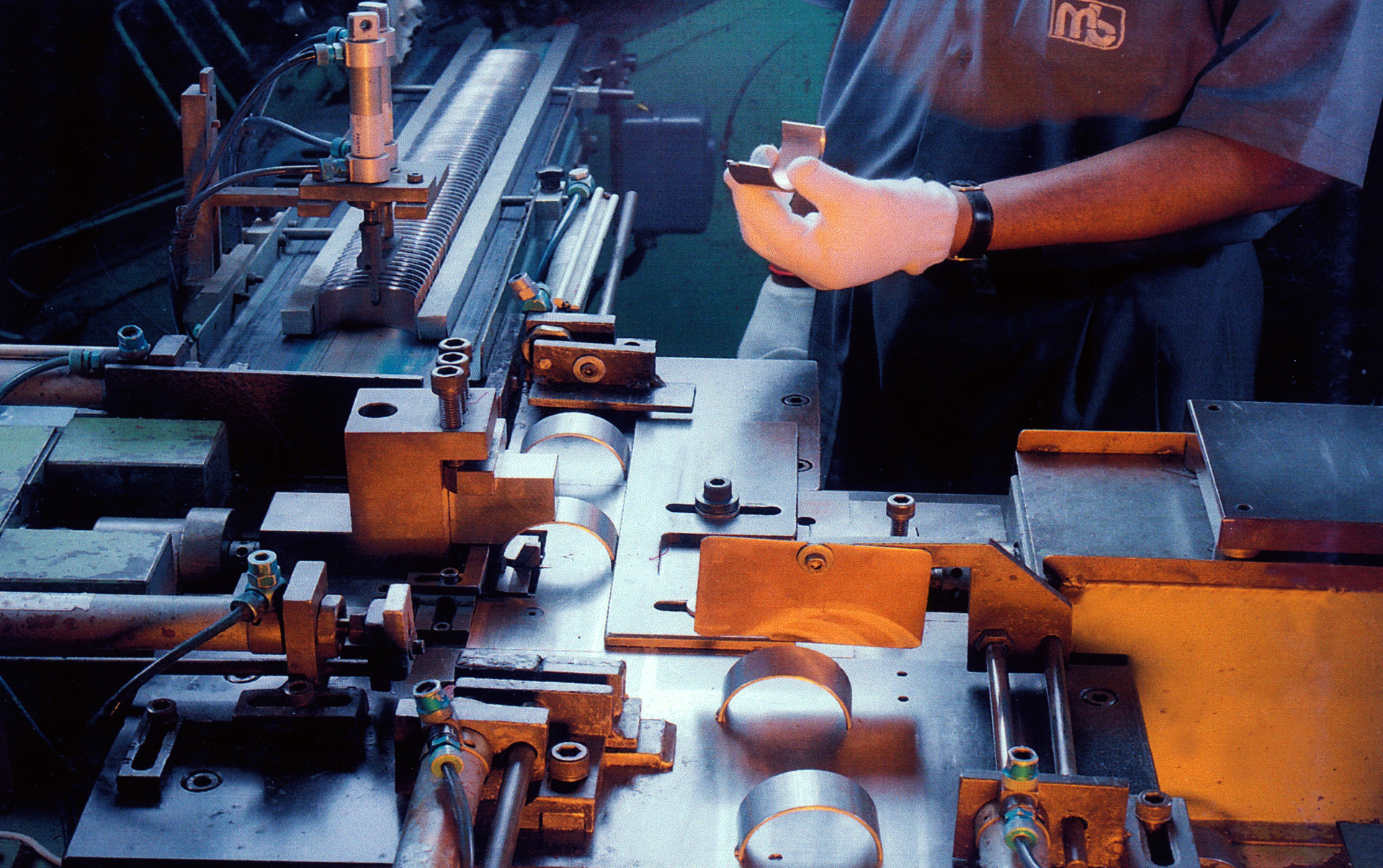

Menon Bearings deploys fully integrated manufacturing facilities featuring a wide array of diverse technologies under one roof to produce & manufacture an extensive & diverse range of critical auto components with advanced tribological properties. Our manufacturing infrastructure can handle a wide variety of metals, coatings, features & diameter ranges. The cellular organization of our manufacturing setup affords flexibility for small batches & at the same time leverages the economies of big volumes. We manufacture 28 million bearings, 40 million bushes & 8 million thrust washers per annum.

OUR EXTENSIVE IN-HOUSE MANUFACTURING & QUALITY SYSTEMS INCLUDE

– Alloy Powder Manufacturing

– Strip Manufacturing :

1. Sintered (Copper, Lead & Tin)

2. Cast (Copper Lead & Tin)

3. Cladded Aluminium & Tin

4. Cladded Aluminium, Tin & Silicon

5. Babbit Material

– Continuous Cast Strip Line

– LTC & Tin flash Plating Line

– Tool Room

– Engine Test Bed

– Material Fatigue Testing Lab

– Research & Design

– Quality System

– SPM Machine Building